As a seamstress, I’m familiar with the saying: she who dies with the most fabric wins. Personally, I don’t want that much fabric.

As a woodworker, I don’t want the biggest stash of hand tools, either. Is a big, full toolbox even necessary to do your work in the shop?

It depends.

And you guessed it…

I have no desire for the biggest tools, either

I like having a working knowledge about tools. It represents independence and self-sufficiency.

That stems from the times my dad and I figured out the whys and hows of the never-ending maintenance problems we tackled in my old childhood house.

We didn’t have the knowledge or the right tools. Truth be told, we did not have access to the places (hardware stores) and people (plumbers, contractors, etc.) in the service desert in which we lived. Our toolbox was a hodge-podge of old, used-to-the-nub castaways. But we never gave up and, yes, we made things work.

Now, besides buying a tool for its stated purpose, I make my decision based on:

- ergonomics

- styling

- cuteness (yes, I do!)

- weight

- size

That’s my philosophy and it’s worked for me 99.9% of the time. Today, I can find a tool in the weight and size compatible to my work style. As a result, I have the ability to manipulate it without damaging my body and joints. For me that is the bottom line.

What is perfectly flat

Conventional thought in woodworking seems to be that a 10 pound hand bench plane helps you achieve perfection and arrive at the flattest finish on a board. It might, but nothing is ever going to get you to perfectly flat using hand tools.

Those philosophical discussions about what flat is or how flat is, well, are just opinions. Due to things like atmospheric pressure (humidity), milling cuts (plain, quarter or flat sawn, etc.), wood preparation, and the skill of the woodworker, flat is only flat in a moment in time.

The wood decides on its own to twist and turn out of flat because that’s its inherent nature! It’s still part of that shapely tree that it came from!

A worker of wood is one who transforms boards to something more. It is important to have a rudimentary impression of what “flat” is. You see it with your eyes. You measure it with a square. Then you cut or shape, or plane to achieve what you need. However, the amount of flatness that is acceptable to you is just that.

Find Out More

That’s a good reason to attend tool events, tool swaps, woodworking conferences, and educational work shops. These are still good places to ask questions, get advice, handle and try out tools.

Also, you might find someone to talk about your own experiences in the shop. Curiosity won’t kill you, but ignorance might.

I believe that getting as much information as you can, to make the best decisions that you can, reduces stress and regret. Still, you’re not one hundred percent in the clear because any decision can generate unexpected results.

Cuts aren’t the only hazard in the wood shop

I don’t have any love for those heavy tools or devices. A 5 pound felling ax or 10 pound plane is just too heavy for me to control or wield for any sustained time.

Starting off, the tool and its effects present exciting prospects as to the results you think you want. Then as the tool weighs heavily in your hands, your form suffers. Successive moves become sloppy and even dangerous.

It’s not the toolbox Olympics

Other factors that play a role are the effects of repetitive motions on the body. Also a realistic assessment of ability and endurance must be done.

Always ask the question: do I have the physical authority to hold and control a tool or any device while achieving the use for which it was intended?

If your answer is no, make adjustments that best protect your hands, muscles, and wallet. This is certainly true if woodworking is what you do for a living.

It’s common sense to be aware that certain movements may hyperextend hand and wrist ligaments. I know this from experience: this is especially poignant during the learning period with a particular tool. In the midst of a project, it is not a good feeling at all.

Good form and follow-through are important in any activity. Athletes know this, musicians practice it, and woodworkers have the opportunity, each day in the shop, to do the same.

A larger tool may require fewer swipes, pushes, or pulls. However, lifting or swinging such a tool, in a sudden gesture, often results in a muscle pull or sprain. This could happen just getting it to the bench!

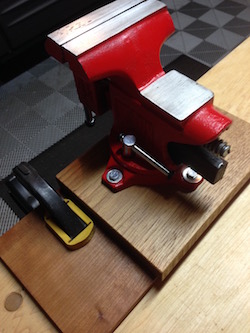

Bench drills, vises, and similar equipment that are not permanently set up on the bench, have their own weight and size issues.

This is truly important in a small shop. These tools are set up on the bench as needed, then taken down once a task has been completed.

Careful selection combats the need for a big, full toolbox

This is a thought that I have shared many times: a smaller tool reduces muscle strain and preserves energy.

All of those things are relative to how you work, physical stature, and ability. It also depends on how you must work. Projects driven by deadlines and profit have their own unique considerations.

I don’t mind getting into the flow of the work, so speeding through it is not my goal.

A 10 pound plane held overhead with one hand is not very smart. The tool was not made for that. The sprains and other maladies that are born of those moments will be dealt with eventually.

Great care must be taken to avoid needless injuries including:

- cuts and bruises,

- repetitive hand and wrist injuries including carpel tunnel syndrome,

- sprained back and neck,

- trips, slips and falls,

- eye injuries,

- mental and physical fatigue.

I purposely choose the smallest tool that will do the job without strain while lifting or using it.

As a result, I don’t feel beat up. And I have a better attitude at the end of my project.

That is this woman’s experience.

About That Toolbox

I, for one, am very appreciative of the variety of hand tool sizes offered today. From the smallest block plane to the largest jointer plane, choices abound.

A little research, testing, and creativity will help achieve the best individualized results for your practice, no matter what size you choose.

So, does having a big, full toolbox mean that you win? Surely, not for me.

For you, the answer is entirely in your hands.

♥️S