A hot dog handle is a shop accessory that helps the user make precise cuts on sawn wood edges. Attached to the side of a bench plane, the hot dog assists in guiding the plane along the edge of a shooting board. Visually, it resembles a frankfurter or a hot dog (without the neon green relish).

The plane/board duo is used to get crisp, straight edges on end grain in this way:

- the hot dog handle is attached to the side of the plane,

- the user makes an extended resting grip on top,

- sidewise and downward pressure are combined on the plane as it is guided along the shooting board rail edge,

- the plane blade action cuts and straightens the edge of the sawn lumber butted against the board.

Keeping the tool kit small

As you know, I try to keep my tool kit small. Yes, I do covet a tool or two. I just don’t have room for everything on my tools wish list, thank goodness.

I’ve taken time to just go through my tool boxes and cabinets to reacquaint myself with their contents. Every space in my small shop is used for storage.

While I work, sometimes I need a tool that’s been hidden away. Naturally, I forget where it is if I haven’t used it in a while. If I can’t find it I have to MacGyver with something else. Inevitably, Murphy’s law kicks in, and I find it after the project is finished! Two strikes.

The Hot Dog Handle

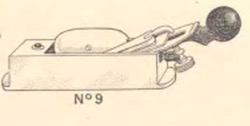

Stanley Rule and Level Company sold a cylindrical, detachable metal handle or hot dog, as a co-accessory to their #9 cabinetmakers miter plane.

The primary uses for the shooting plane were cleaning up miters and jointing with a shooting board.

Then the Shooting Plane

The hot dog handle was adapted by woodworkers for use on the #51 shooting plane.

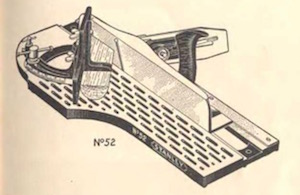

The #51 plane, paired with the #52 shooting board, planes flat board edges as well as miters. Manufactured by Stanley from 1905 to 1943, the premium tool set weighed almost 18 pounds.

The Stanley plane and miter board were offered as a premium tool set not for the average woodworker’s shop. It just made it easier to get nice, clean precision cuts.

The Stanley #51 was a dedicated plane meant to be used exclusively for mitering and jointing. The L-shaped plane was guided along the shooting board rail. The bladed sole was guided along a board edge on the shooting board table. The tool was hardly meant to do anything else.

The shooting plane and the board were made from heavy cast metals, not steel.

Shooting Planes Haven’t Changed Much

Modern age toolmakers have their own take on the shooting planes. They are meant to be used for any task, including trimming miters, end grain, edge grain or long board edges. The concept of pairing the plane with a shooting board was retained.

Plane makers employ modern alloys and materials in their production processes. Design features pay homage to the tools of old, but innovations have had a positive impact.

Tool efficiency and function, however, are not always appreciated by buyers. We do not think or care about anti-fracking, anti-bubbling, anti-flaking, or anti-rust properties, until something happens. After a literal storm in a wood shop full of humidity these inhibitors may buy some time.

Are heft and length necessary?

I have tried the modern shooting planes at tool events and woodworking workshops. I love them all.

These new planes are hefty and smooth in their operation. The shooting planes do the job without a lot of effort. I can certainly justify buying them all, but I only have two hands and a bench in a small wood shop.

I do not love the heavy weights. A tool weighing over 8 pounds, along with its considerable price tag, gives me great cause to pause. That’s right, they’re usually the most expensive planes in the plane hierarchy. The modern version of the hot dog handle is an investment, too.

I am trying my best to stay in my budget lane and fully utilize the tools I have. Of course, this means using them as described and adapting them in unconventional ways to solve problems in the shop.

Nowadays, in keeping with my woodworking value of a minimal tool kit, I use my low angle jack plane for mitering and shooting board edges.

Revamping the hot dog

I like the idea of a specifically made, single-purpose shooting plane. Having a lot of tools like that on (infrequent) call is a bit wasteful to me.

I keep my budget in mind when I am searching for tools. Sometimes I feel guilty about desiring a tool, especially one that is expensive. The actual guilt of spending so much money can be powerful. So, I decided that a useful alternative is my own version of the hot dog handle and adapting it for use in my shop.

As you will see, I made it big enough to comfortably hold. In addition to slippage, the smaller metal hot dog handle is cold and invites hand cramping.

I envisioned a bigger handle made from wood, shaped like a mouse. The thumb- and finger-holds (holes) in the handle help me guide the plane. This prevents my hand from sliding forward and off of the new handle.

This is What I Did

I used scrap pieces of butternut to make the body. Between two pieces, 3/4″ and 1/4″ thick, I sandwiched a narrow 1/8″ thick slice.

Then, I rooted into the narrow 1/8″ slip and made a deep dado groove or channel with a very narrow 1/8″ chisel. Paring chisels were used to finesse the groove. Finally the hotdog was pressure fitted or slipped over the plane’s left side wing.

When needed, I attach it to a tool I already have – my well-used low angle jack plane. I don’t have to buy a single purpose tool.

A shop made shooting board made from scrap maple and purple heart completes the set up.

The Benefits

The efficiencies in the shop automatically increase for me. I’m maintaining my confidence by adapting and using a tool that I am comfortable with.

I don’t need to purchase a jointer or shooting plane.

The hot dog handle, blade angle adjustments and fine tuning of the plane mouth opening enable me to multitask my low angle jack plane.

Now, I can rough out boards by adjusting the mouth to get thicker and heavier wood shavings.

After that, I can final finish boards by using a sharp blade and narrowing the mouth of the plane and getting the finest of shavings.

And I can shoot both edge and end grain on my shooting board.

This works for me.

💚S