A striking axe or old forged froe is a hand tool used to cleave logs. It is suited for riving billets, chair legs and spindles, shakes and shingles, and any application calling for straight grain wood.

Along with related tools like axes, wedges, saws and adzes, froes are prominent in green woodworking. Generally, that branch (pun intended) of woodworking starts with trees and logs obtained directly from the forest, not the lumber yard.

Fallen timber

After recent storms, I found a few fallen logs to chop for practice. The logs were quite wet and almost equally heartwood to sapwood. I let them stand for more than two months before reaching for them again. They were still obviously moist. This is good for green woodworking projects such as shrink pots and bowls where ongoing shrinking is desirable. It is difficult to find this kind of wood in the city, so I look on the street for branches and logs that have been displaced.

After a rainstorm, there’s no sleeping in. I get out early in the morning before the branches and logs are picked up by the public works department. Nowadays, they are fast and efficient, collecting the wood detritus from the curbs. They mulch all but the biggest logs on the spot.

Finding an old forged froe

Tool swaps, old barns, and the extranet are good sources for finding a froe. You may have already seen one and passed on buying it.

I found a froe in good condition. It had a forged blade that was authentically craggy. The blade just needed a little cleaning. Then I smoothed the edge with a file.

A froe blade edge does not have to be chisel sharp since that would not help in cleaving wood logs. When the top of the blade is struck, the wedge shaped knife edge transmits a shock to the log. The log responds by splitting along natural grain lines. It is actually intriguing to see it split under the pressure. The sound of crackling wood is primitive and organic.

The old wood handle of the froe I found was blackened from many years of use. Also, a couple of big flat head screws were pinned near the eye of the blade. This keeps the blade from sliding off the handle during riving.

Pinning is often done when the tool has been in use awhile. The user doesn’t have time to make a new handle, so a nail or screw is driven in the handle near the blade. It functions like a permanent wedge. Sometimes it works; sometimes it doesn’t. When it works, the user keeps working. Of course a proper repair is forgotten after the job is done.

Still, I do not like using old tool handles that look like they lived in the muck and mire of middle earth! The only solution for me was to cut it off and replace it.

A new handle for an old tool

I fastened an elm wood branch in the end vise and started taking off the bark with both straight and curved drawknives.

The froe mallet

Froe mallets need a lot of mass to drive the blade into the log. It is definitely a cave-woman’s tool. The trick is to balance the weight of the mallet with your ability to wield this thing without injury to yourself!

Watch this video of my attempt to rive a full shake from a short log:

Success!

Riving is hard work! I sweat more doing this than I did during my early morning 10 mile walk in 80 degree heat.

Granted, the froe blade is traditionally dull at its edge but I may sharpen it slightly. The hardest part was getting the blade to bite into the log’s edge. After that the rest of the blade sank into the body of the log with many hard whacks.

Do you know what the action is? It’s twisting that old forged froe and still relying on the wood to split along natural lines. I followed through until the shake released itself from the log.

Drop the mic moment

Each time a shake falls away, it feels like a “drop the mic” moment. I suppose it can be satisfying to see, ultimately, a mountain of shakes build up in front of you.

Riving is an exercise all by itself. I twisted the froe with a bit of effort. I can’t imagine how anyone fulfilled the requirement for hundreds, maybe thousands of shakes used for a roof or siding in early houses. It requires a lot of physical effort and time. On top of that, enough wood has to be sourced to complete the task.

Each woodworker has their own preference and resources for splitting logs and wood. Although froes are not used to “split” a log in half, the length of the blade must be considered. It should be longer than the width of the log in order to preserve contact with the mallet. The mallet may slip and cause injury to the user (ask me how I know). Once the blade disappears into the log, it is time to stop beating!

Riving brakes

Contraptions called riving brakes “trap” or stabilize long wood logs and billets. They provide leveraged work-holding for striking the froe with the mallet. A quick study of the wood is then made enabling accurate predictions regarding the direction of the splits. The direction can be controlled to a degree. Similar to a vise, turning and moving the log on the brake helps the user best position the work. It acts like a third hand. The brake may be formal or informal structures made from:

- naturally intertwined or forked tree branches,

- wood boards built into a configuration of openings and stops,

- splits in downed tree logs,

- anything that works.

Of course, it must be strong enough to withstand the log being manipulated and twisted with the froe and pounded by the mallet!

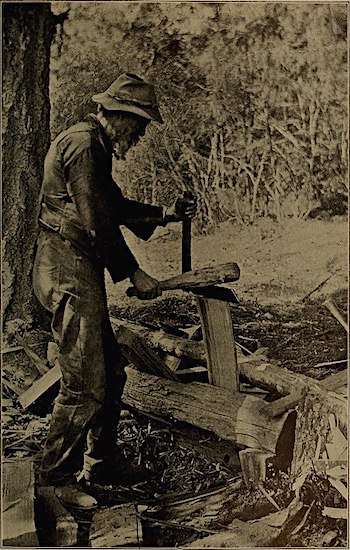

an old forged froe. The long shake is in a riving brake

improvised from a recessed split in a large log: 1885

(Wikimedia commons)

Imagine the task of using an old forged froe to make enough shakes to cover the roof and sides of a house.

The donor elm

The shakes, made from elm are beautiful. The grain fibers are somewhat straight. It presents boldly, however, and unpredictably undulates over a small knot in one corner of the log. It gives the shakes and the resulting siding or roof a lot of character.

Elm trees are tough hardwoods with softwood tendencies. The species has been used since antiquity for boatbuilding, coffins, even as water pipes. It resists decay when wet but in my part of the country Dutch elm disease is an ongoing problem. Unfortunately, many trees have succumbed. Efforts to combat the disease through research, transgenic grafting, and planting other tree species as replacements seem to be working. It will take years to see the results.

I discovered that hops used to make beer, cannabis, and nettles are all related to the elm. Each have their own vexatious presence on this planet. As it is for humans, we can choose our friends, but not our family!

For now, I’ll put aside the remnant log and the riven shakes. They will continue to dry and provide an opportunity for me to observe changes in the wood over time. As they dry, I’ll rive a few more shakes with that newly refurbished old forged froe. I will let you know what I discover.

In the meantime,

The tree is more than first a seed, then a stem, then a living trunk, and then dead timber. The tree is a slow enduring force straining to win the sky.

– Antoine de Saint-Exupéry

Baadaye.

💚 Shirley J